Introduction

In today’s rapidly evolving technological landscape, the integration of artificial intelligence (AI) into various sectors has become increasingly significant. AI is not only transforming software applications but is also profoundly impacting computer hardware development. This intersection of AI and hardware signifies a paradigm shift, where intelligent systems are now influencing not just how devices operate but also how they are designed and manufactured. The ability of AI to learn from data and improve performance dynamically is paving the way for more efficient and powerful hardware solutions.

However, the advancement of AI-driven hardware development does not come without its challenges. Hardware developers face a multitude of issues, such as the need for specialized skills, the complexity of designing AI-compatible architectures, and the constant demand for innovation. Moreover, as AI algorithms become more advanced, the hardware must evolve accordingly to harness the full potential of these intelligent systems. Issues like energy consumption, processing speed, and cost-effectiveness also necessitate a careful balance between performance and sustainability.

This blog post aims to delve into the evolving relationship between AI and computer hardware development. Readers can expect to gain insights into how AI is driving innovations in hardware design, the emerging trends shaping the industry, and the implications of these changes for both professionals and technology enthusiasts. Understanding this intersection is crucial for anyone invested in the future of technology, as it informs not only development strategies but also market trends and user experiences. Through this exploration, we will highlight how AI not only enhances the capabilities of hardware but also redefines its purpose in the modern digital era.

The Role of AI in Enhancing Hardware Design

Artificial Intelligence (AI) is revolutionizing hardware design by offering exceptional capabilities that lead to improved efficiency and innovation within the development process. One of the most significant contributions of AI in this realm is its ability to optimize designs through advanced algorithms. By analyzing vast datasets, AI can identify design flaws and provide suggestions for modifications, shortening the design iteration cycles that have traditionally proved to be time-consuming. Techniques such as generative design allow engineers to input their specifications and constraints, while AI explores an extensive range of possibilities far beyond manual capabilities.

In addition to design optimization, AI-driven simulation tools play a critical role in modeling hardware performance before the physical prototypes are created. By conducting thorough simulations, developers can evaluate how various components of a design will perform under different conditions, thus reducing the likelihood of costly failures in later stages. Research indicates that hardware designs enhanced by AI simulations can achieve up to a 30% reduction in the time spent on testing and validation, a fact supported by numerous case studies in the tech industry.

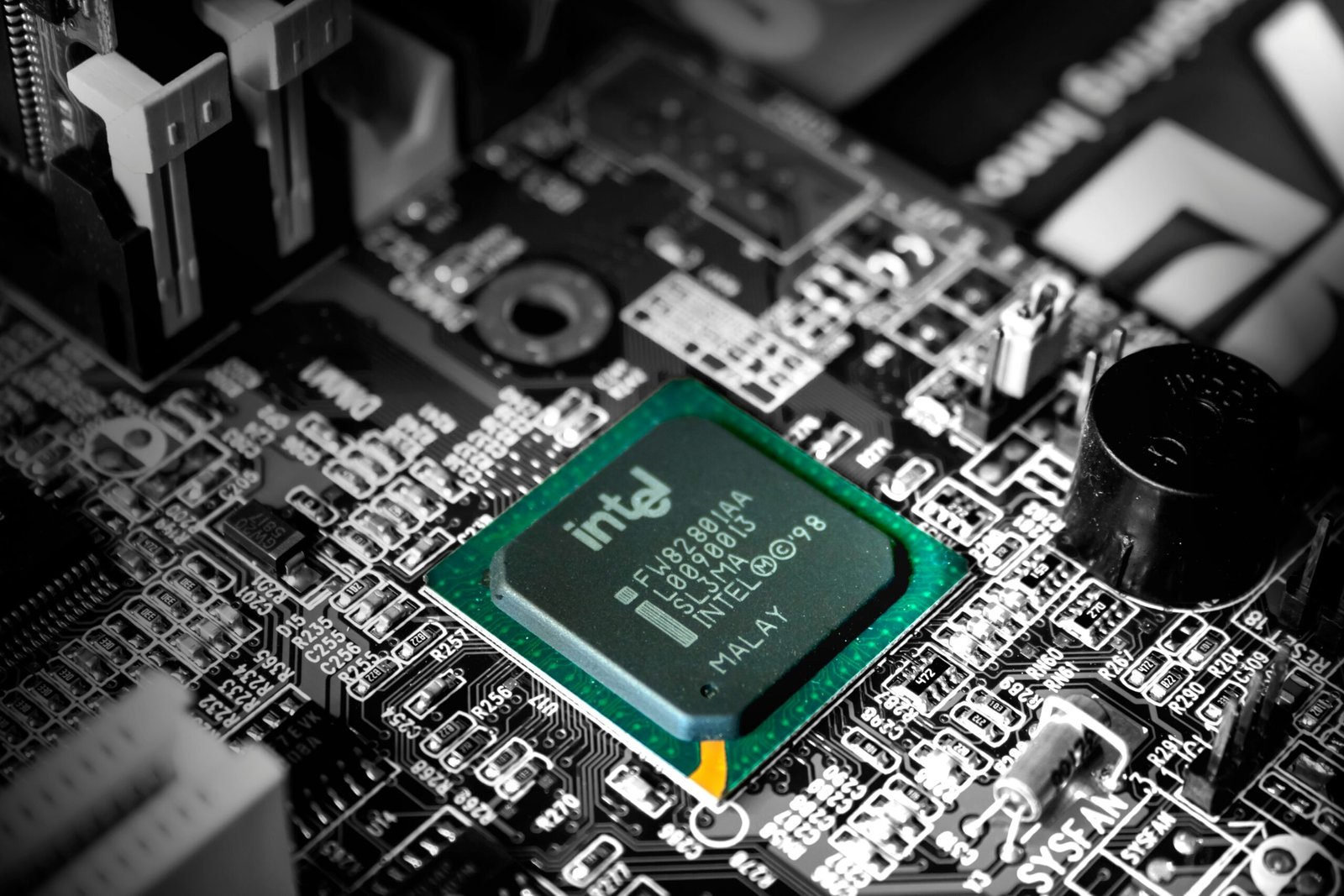

Moreover, AI contributes to predicting potential hardware failures by using machine learning algorithms that analyze patterns in performance data. This predictive maintenance approach allows hardware teams to proactively address issues before they escalate, further enhancing reliability and longevity. For instance, companies such as Intel have implemented AI solutions that monitor manufacturing processes and predict equipment malfunctions, resulting in a significant decrease in downtime.

Collaboration among hardware teams also benefits from the integration of AI technologies. AI tools improve communication and resource management by streamlining workflows and ensuring that team members can access real-time data and insights. This integration accelerates the product development lifecycle, allowing teams to bring innovative hardware solutions to market more rapidly.

AI’s Influence on Hardware Manufacturing Processes

The intersection of artificial intelligence (AI) and hardware manufacturing has become a focal point in the quest for increased efficiency and enhanced product quality. One of the most significant contributions of AI in this realm is the automation of production lines. Automated systems driven by AI algorithms can manage and streamline the assembly process, resulting in faster production cycles and reduced labor costs. These intelligent systems can adjust parameters in real-time based on data analytics, facilitating a dynamic manufacturing environment that adapts to varying demands.

Predictive maintenance is another area where AI proves invaluable. By utilizing machine learning techniques, manufacturers can analyze data from machines to foresee possible failures before they occur, thus minimizing downtime. This proactive approach not only safeguards equipment longevity but also ensures that production schedules remain uninterrupted, leading to higher overall operational efficiency and cost savings.

Quality control measures have also seen transformative changes due to AI integration. Traditional methods, often reliant on manual inspection, are increasingly being supplemented or replaced by machine learning algorithms capable of identifying defects with high accuracy. For instance, industry leaders such as Siemens have implemented AI-driven quality assurance processes that automatically flag defects during production, allowing for immediate corrective actions to be taken. This shift towards intelligent inspection systems enhances product quality and significantly reduces the occurrence of recalls or post-production issues.

Furthermore, AI optimizations extend into supply chain management, where data analytics algorithms predict demand trends and streamline inventory processes. Companies like Dell leverage AI to maintain an agile supply chain that can swiftly respond to market changes. This strategic advantage not only reduces operational costs but also improves customer satisfaction by ensuring timely delivery of products.

Incorporating AI into hardware manufacturing processes has become essential for maintaining competitiveness in a rapidly evolving market, highlighting its critical role in transforming traditional manufacturing paradigms.

Challenges and Future Directions

The integration of artificial intelligence (AI) into computer hardware development is not without its challenges. One significant barrier is the necessity for compatibility between existing hardware systems and new AI technologies. Achieving seamless integration requires careful planning and substantial investment, often leading to budgetary constraints for many manufacturers. Organizations must assess their current infrastructure and identify potential upgrades or modifications needed to accommodate AI functionalities. Such transitions may incur unforeseen costs and complications, posing a significant challenge for businesses and engineers alike.

Another pressing issue is data privacy. As AI systems require vast amounts of data to train and improve their algorithms, manufacturers must ensure robust safeguards against data breaches and unauthorized access. Balancing performance optimization while adhering to stringent data protection regulations complicates the implementation of AI solutions. This concern is heightened as businesses increasingly adopt AI applications, raising questions about the ethical implications of data usage and transparency within the hardware sector.

The skills gap among current hardware engineers also poses a challenge. As AI technologies evolve rapidly, many engineers may find their expertise outdated or insufficient to keep pace with innovations. Continuous education and training are crucial for ensuring that the workforce can effectively leverage AI in hardware development. Companies must invest in upskilling initiatives to empower their teams, thereby maintaining a competitive edge in an increasingly automated landscape.

Looking forward, the influence of AI on hardware development is expected to foster emerging trends and opportunities. Innovations such as neuromorphic computing and quantum computing present new frontiers in hardware design, potentially revolutionizing current paradigms. As AI capabilities expand, the hardware industry stands at the cusp of significant transformation. It is crucial for stakeholders to consider the balance between AI innovations and human expertise in driving future advancements. We invite readers to share their thoughts and experiences regarding the ongoing impact of AI on computer hardware development, fostering a collaborative dialogue within this rapidly evolving field.